Wires:

ISWP –Wire mill is one of the oldest wire plant in India. It was established in 1920. We have modernized the plant over time and currently we have state of the art manufacturing facilities for producing various types of Wires and Wire Products. All the Wires and wire products are manufactured as “TATA WIRON” brand.

We are committed towards creating and maintaining a healthy and pollution-free environment, and are forever dedicated towards new and more environment-friendly ways of conducting and managing our operations. Our Wire Drawing plant is one of the very few in the country that employs the environment friendly mechanical process of descaling. We also use an environment friendly fumeless pickling process in our Galvanizing Plant.

The Wire Mill has an annual capacity to produce 55000 MT of drawn HB Wires, 48000 MT of Galvanized Wire, 12000 MT of Barbed Wire, 1500 MT of Chain Link, 5000 MT of Pre-stressed Concrete Wire and 15000 MT of Binding Wire.

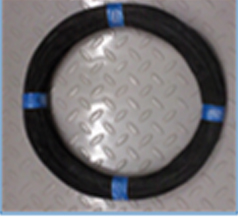

GI Wire (Galvanized Iron Wire)

GI Wire (Galvanized Iron Wire) is a zinc coated steel wire used for applications like agriculture, fencing, poultry, grape farming, etc.that demand longevity and corrosion resistance. ISWP manufactures GI wire in our state of the art facility using ‘Hot Dip’ technology to ensure durability and long lasting resistance to corrosion.

Our GI wire product range is as mentioned below:

-

Product Size Grade Specification Application Photograph GI Wire 1.60 to 4.00mm TW01 Higher Coated(90-120 Gms/m2) Used for making cages in poultry farms etc.

1.60 – 4.88 mm TW02 Medium Coated(50-80 Gms/m2) Used for fencing products as Barbed Wires&other industrial purposes.

2.00 – 2.50 mm TW03 Low Coated(30-60 Gms/m2) Used for redrawing to thinner sizes.

1.60 – 4.00 mm TW05 Medium Coated(60-90 Gms/m2) Used for farming to grow plants etc.

2.33 – 3.76 mm TW07 Medium Coated (40 – 70 Gms/m2) Used in construction for reinforcements, etc.

2.50 – 4.00 mm SFCL Medium Coated(50-80 Gms/m2) Used for making Chain Link fences.

Barbed Wire

Barbed Wire is manufactured with in house produced GI wire which has uniform zinc coating and wire thickness. Barbed wire produced is with longer barbs at uniform distance. These are mainly used in fencing of agricultural and commercial fields & boundary walls.

Chain Link:

Tata Wiron GI-D fence Chain Link is made of high quality zinc coated steel wire. They are extremely strong and built to last long. They offer significantly more length per kg. It has exact mesh size with no in-congruency. The product is available as compacted bundles. These are produced in fully automatic weaving machine to have exact mesh size and congruency.

Our Product range of Barbed Wire and ChainLink is as mentioned below:

-

Product Size Grade Specification Application Photograph Barbed Wire 2.0 x 2.0 mm Coil Weight – 26 – 26.5 Kg Pitch – 100 mm Line Wire – 2.00 mm Point Wire – 2.00 mm Used for fencing purpose in commercial, agricultural fields, etc.

2.2 x 2.2 mm Line Wire – 2.20 mm Point Wire – 2.20 mm 2.5 x 2.0 mm Line Wire – 2.50 mm Point Wire – 2.00 mm 2.5 x 2.5 mm Line Wire – 2.50 mm Point Wire – 2.50 mm Chain Link Wire 2.50 mm

2.64 mm

3.00 mm

4.00 mmMesh Size- 2 x 2inch, Width – 4ft,5ft,6ft

Length – 50ft,100ft

End Type- Knuckle & TwistUsed for fencing purpose in industrial, commercial,residential fields etc.

Mesh Size- 3 x 3 inch, Mesh Size- 4 x 4 inch

Pre-stressed Concrete Wires

Pre-stressed Concrete Wires find extensive usage in concrete reinforcement of electric poles, pre-stressed concrete pipes, concrete piles, and railway sleepers. Our pre-stressed concrete wires are tested for size, breaking load, tensile strength, elongation, yield strength and any other customer specific requirements. It is produced in 4mm size and in both indented and plain form.

Binding Wires

Binding Wiresare used in construction fortying reinforcement bars and miscellaneous binding applications. We produce binding wire in 1.22mm, 0.91mm,0.71mm and 0.61mm diameter sizes. Coil weight is 30kg PIP (Pack in Pack) – 6 units of 5 kg pack as shown in picture below.

Binding wires are drawn to required sizes in 2 stageof wire drawing through automatic wire drawing machines. They are annealed in fully automated annealing furnaces to achieve required mechanical properties.

Major features of our Binding Wires are:

- Consistent diameter

- Unmatched ductility and strength

- Softness: Easy to use

- Unique and secure packaging with ease of handling

- Quicker tying, saves time

We conform to the highest standards when it comes to our product quality and the following BIS licenses stand testimony to this commitment.

- IS 1786-2008

- IS 6003-2010

- IS 280-2006

- IS 16644-2018

In fact, we are the first Company in India to have received the IS 16644-2018 license for high-carbon PC wires.